|

| October 05, 2021 | Volume 17 Issue 37 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Cobots come to the rescue in packaging and supply chain industries struggling with labor shortage

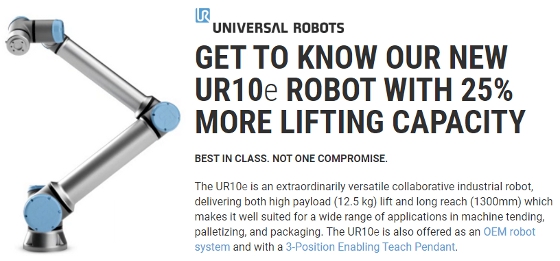

As labor issues persist, Universal Robots, the pioneering leader of collaborative robotics, demonstrated to PACK EXPO attendees its latest automated solutions for hard-to-staff tasks such as box erecting and palletizing. Powering many of these applications was the company's most popular cobot, the UR10e, now able to lift 25% more.

The Covid-19 pandemic has made it abundantly clear that to overcome the challenges of rising delivery expectations, growing labor shortages, and expanding order volumes, the packaging industry will need to embrace automation at a rapid pace. Collaborative robots (cobots) are now increasingly a part of that solution, a trend reflected in the rise of cobot leader Universal Robots that saw a remarkable 75% growth in revenue year-over-year in its most recent global quarterly result.

Ease-of-use is redefined with the Robotiq Palletizing Solution featuring a UR cobot. Open the box, and the hardware and software is already connected and ready to install. Plan your program in just three steps, directly on the robot control device, with the Robotiq software suite's Material Handling Copilot.

After a two-year hiatus, PACK EXPO 2021 in Las Vegas, held September 23-26, was the packaging industry's first in-person opportunity to experience Universal Robots' longest reach cobot, the UR10e, featuring a new total payload of 12.5 kg (27.55 lb), showcased in Universal Robots' PACK EXPO booth C3545.

"That's a 25% increase in payload and a 0% increase in the price of the cobot, giving a significant boost to palletizing applications at no additional expense," said Joe Campbell, senior manager of applications development at Universal Robots. "That means you can move more per pick, use heavier tools, and process heavier parts, supported by the 1,300-mm reach (51 in.) and small footprint that makes the UR10e our best seller."

The enhanced UR10e cobot from Universal Robots handles 25% more payload.

The enhanced UR10e's greater payload also takes more weight from the hands and shoulders of humans, leading to improved ergonomics and working conditions. With overexertion and repetitive motion accounting for an estimated 24% and 8% of workplace injuries respectively in the U.S. alone, this provides significant relief to human workers.

While UR focuses on developing the best cobot arm on the market, the company collaborates with more than 400 third-party companies that develop peripherals and application kits certified by UR for seamless compatibility with UR cobots. The products are available through the UR+ platform, the cobot industry's largest ecosystem, assisting manufacturers to automate quickly and easily.

Palletizing redefined

At Universal Robots' PACK EXPO booth, the UR10e was showcased powering UR+ partner Robotiq's Palletizing Solution that redefines ease-of-use. Manufacturers simply open the box to find the hardware and software already connected and ready to install. Programming happens in just three steps, directly on the UR10e cobot's teach pendant that runs Robotiq software suite's Material Handling Copilot. The Copilot automatically generates and optimizes all trajectories and robot movements based on the pallet design, matching line throughput.

UR+ partner Robotiq's Palletizing Solution can handle up to 13 boxes per minute.

Robotiq's Palletizing Solution can be programmed quickly and easily on the UR10e cobot's teach pendant.

Automate erecting and taping boxes

To fully optimize end-of-line tasks, automating the erecting of cardboard boxes is key. The box EZ by Flex-Line Automation efficiently solves this tedious job. The box EZ was showcased at UR's PACK EXPO booth powered by the UR5e cobot. It is a collaborative box-erecting solution with a small footprint, providing unmatched flexibility that is easy to deploy. It erects multiple sizes of boxes and can automatically replace them in a queue so that users never run out of the box size they need.

The collaborative box erector can utilize different cobots, including the UR5e or UR10e, to erect and tape various sizes of boxes to streamline your shipping processes.

"We were delighted to leverage the rich ecosystem of UR+ products and kits to show PACK EXPO attendees hands-on what cobot-powered packaging automation can look like in their facilities," said Campbell.

Source: Universal Robots

Published October 2021

Rate this article

View our terms of use and privacy policy